Making ideas concrete

As a purposeful technology partner, we ensure smooth operations with consistently high quality and optimised resources, whether in ready-mix concrete and precast concrete components, or dry batch and bulk material. We control production and digitalise processes.

Since its foundation in 2018 our team in Australia and New Zealand is there for you each step of the way, from start of the project to configuration, implementation, and follow-up support. Dorner employs almost 100 people in Austria as well as in its subsidiaries in Perth (Australia) and Auckland (New Zealand).

Products and Services

We are providing automation solutions and software products for concrete manufacturers and ensure stable and efficient production processes. Our technology makes a difference in a comprehensive and effective way. Sustainable functionality is just as important to us as attractive design.

Intuitive control

dornerBatch

- Intuitive

Attractive and user-friendly thanks to UX design. - Precise and efficient

Dosing accuracy, self-learning systems, resource efficiency with maximum output. - Future proof

Configurable technology, regular updates and new features.

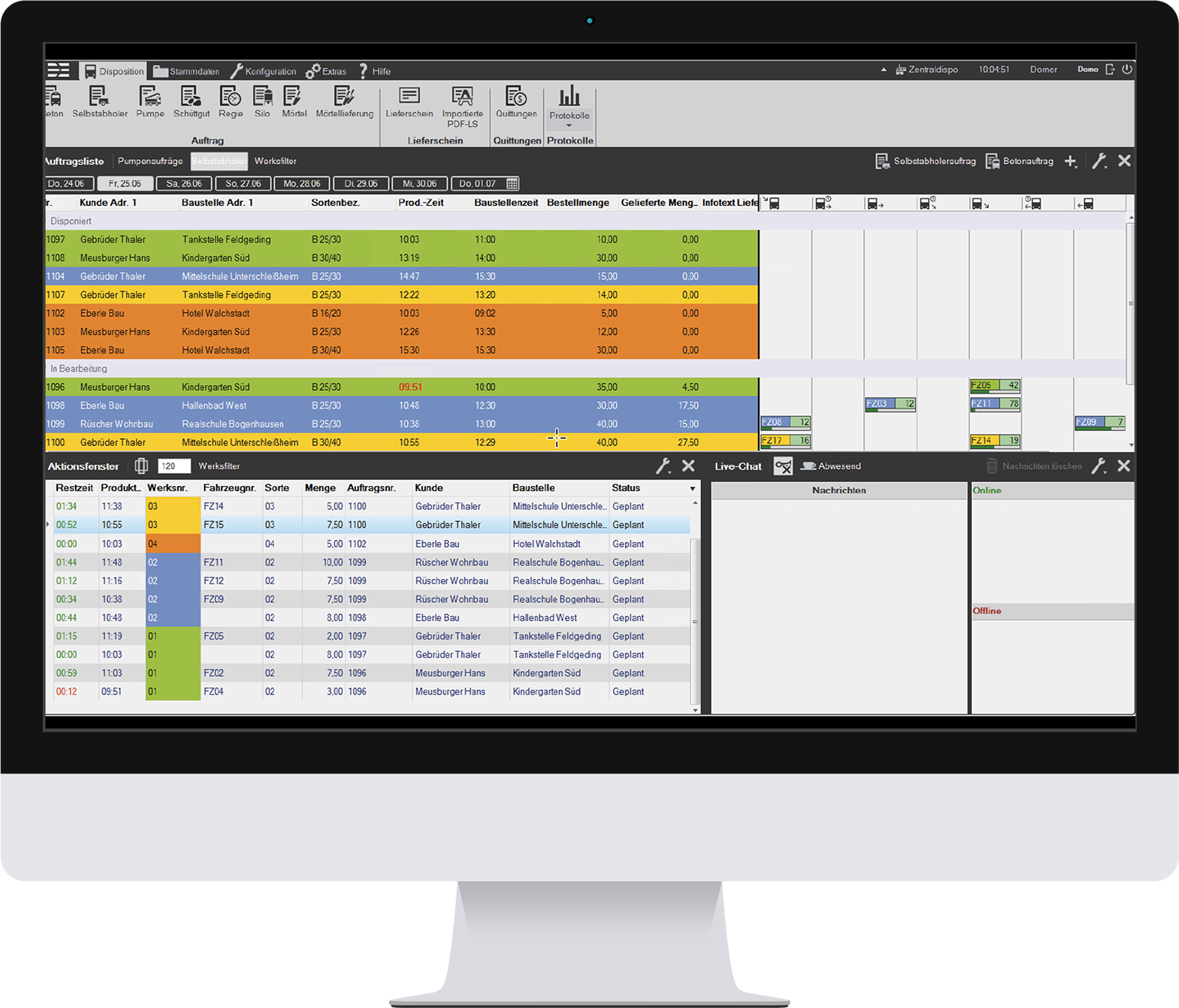

Efficient dispatching

dornerOptimize

- Centralised order entry and fleet optimisation.

- Gives the dispatcher comprehensive factory and vehicle insights.

- Order lists and trip schedules are updated in real time.

- Optimisation algorithms allow for the efficient use of resources.